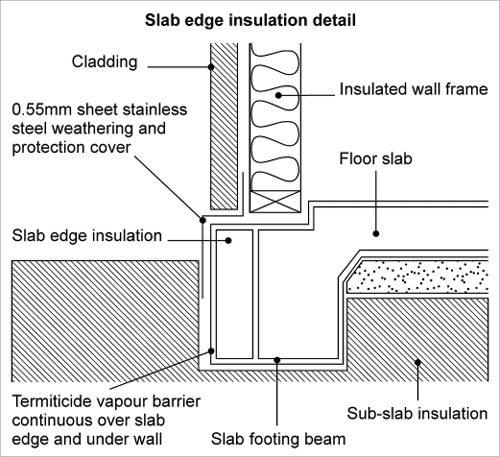

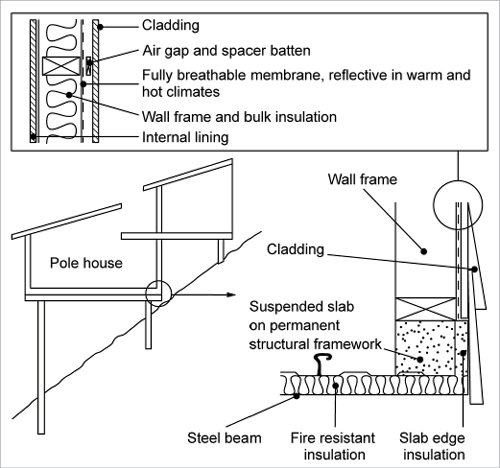

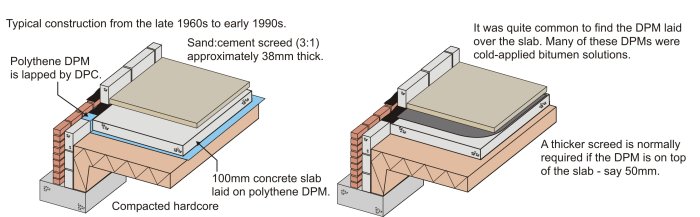

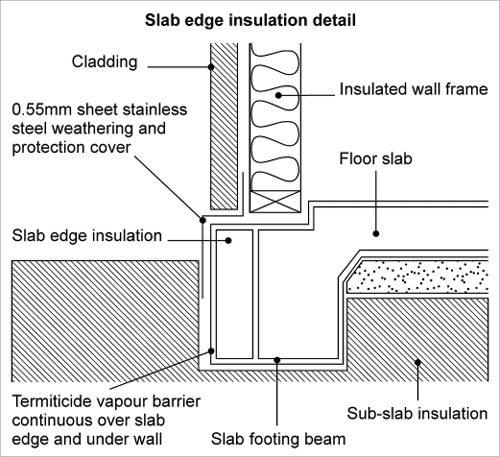

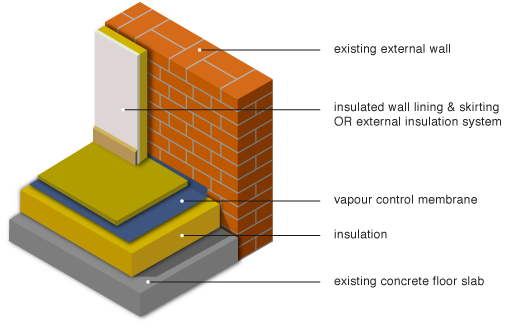

SOLID FLOOR INSULATION OVER SLAB To meet min U value required of 022 W/m²K Solid ground floor to consist of 150mm consolidated wellrammed hardcore Blinded with 50mm sand blinding Provide 100mm ST2 or Gen2 ground bearing slab concrete mix to conform to BS over a 10mm gauge polythene DPM, DPM to be lapped in with DPC in walls Floor to be insulatedTechnical Details 2 1 Solid Ground Floor Construction 3 11 Types of comprised boarded suspended timber floors on sleeper walls, with solid floors of quarry tiles laid directly on the earth or a bed of ashes mainly restricted to basements, kitchens and outhouses However, between the wars the wider availability of Portland cement enabled reinforced concrete ground floors toFigure B10 Figure B10 Alternative Floor Slab Detail The suspended reinforced concrete

How To Design An Ideal Floor For Warehouse And Logistics Facilities

First floor suspended concrete slab detail

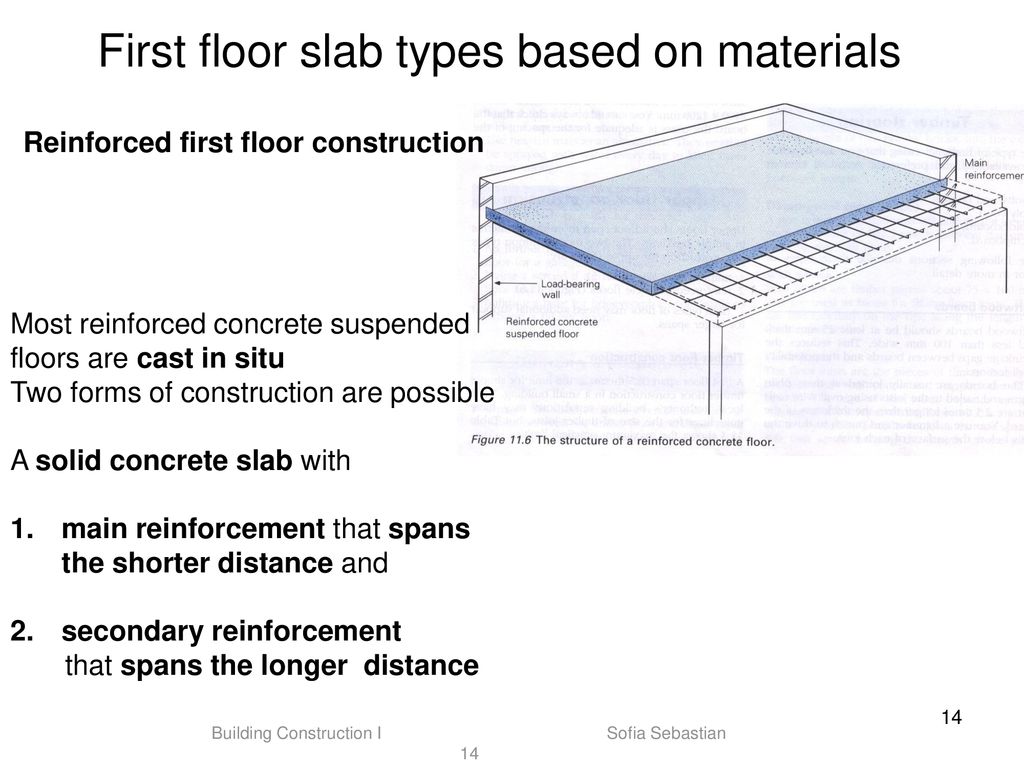

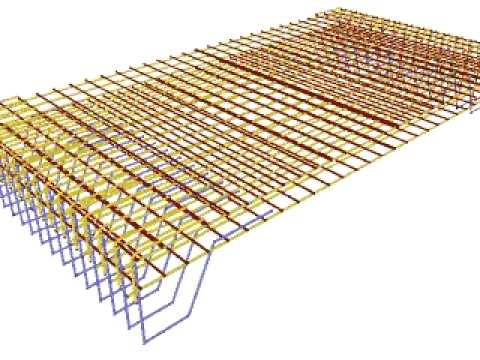

First floor suspended concrete slab detail-This article is the first in a series on recommended reinforcement details for castinplace concrete construction Twoway slabs are generally defined as suspended slabs where the ratio of the long to the short side of a slab panel is 2 or less In twoway construction, load transfer is by bending in two directions The main flexural reinforcement usually consists of two mats ofSuspended timber floor As a requirement of the Building Regulations the structure should be protected against the growth of weeds and other plantlife The ground should have a layer of concrete poured across and there should be a ventilated gap of at least 150mm between the underside of the timbers and the concrete, to prevent moisture gathering and affecting the

Concrete Slab Floors Yourhome

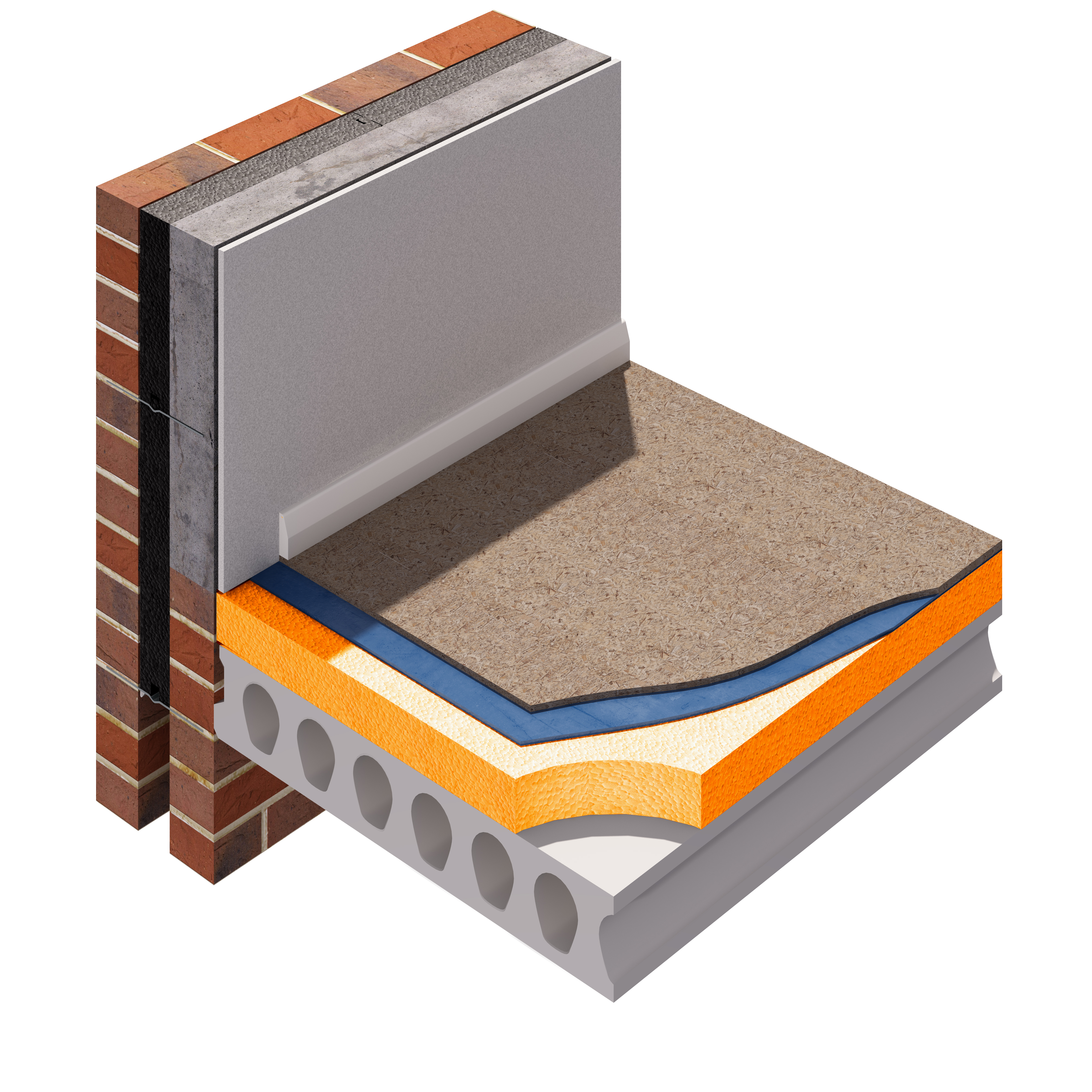

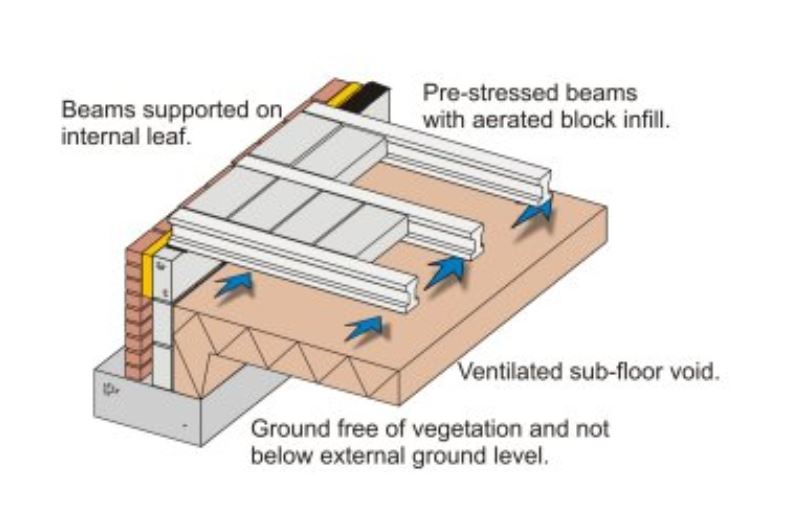

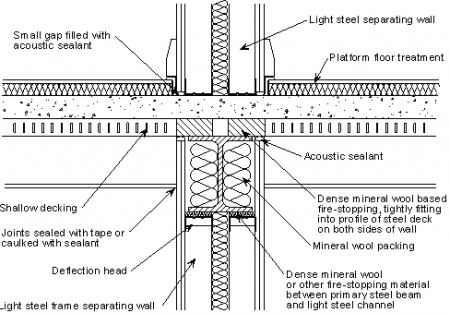

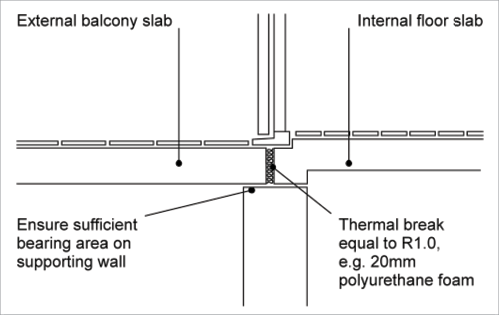

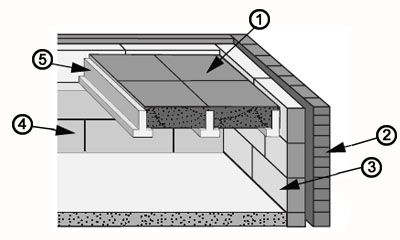

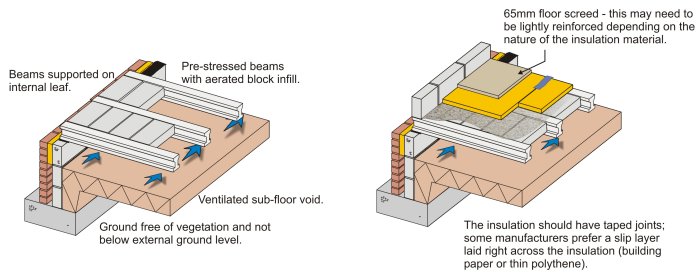

The floor slab may be in the form of a precast concrete system comprises a shallow and asymmetric Westok cellular beam with reinforcement placed through the cells to anchor the slab to the beam This simple detail provides a straightforward and costeffective disproportionate collapse detail and is also used to resist torsion in the final condition For composite slabs withA suspended concrete floor is a floor slab where its perimeter is, or at least two of its opposite edges are, supported on walls, beams or columns that carry its self weight and imposed loading The floor spans between supports and will normally deflect under load to a dimension that is limited by the design used The prestressing of a concrete floor slab can eliminate its usual deflection Instead of timber joists, suspended concrete floor constructions use precast concrete planks or smaller, precast concrete beams with concrete blocks laid in between They are often preferred, as they can span greater distances than timber joists can Any insulation being installed should also be placed between the beams, and air vents must be placed underneath to

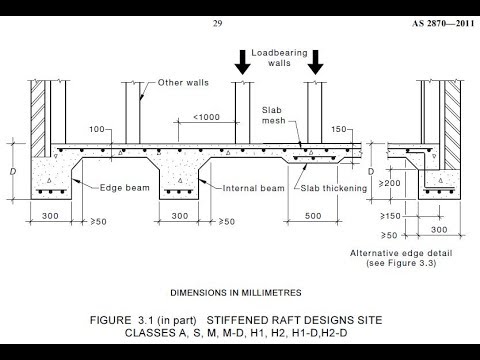

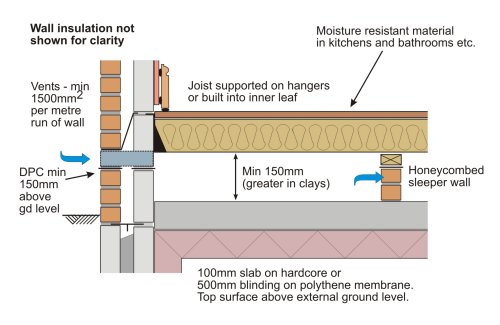

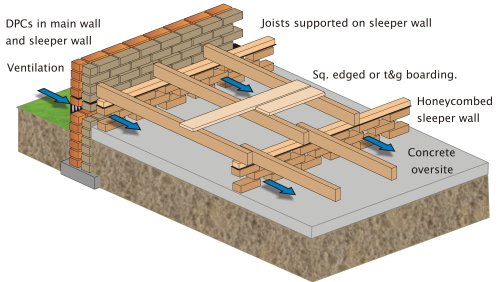

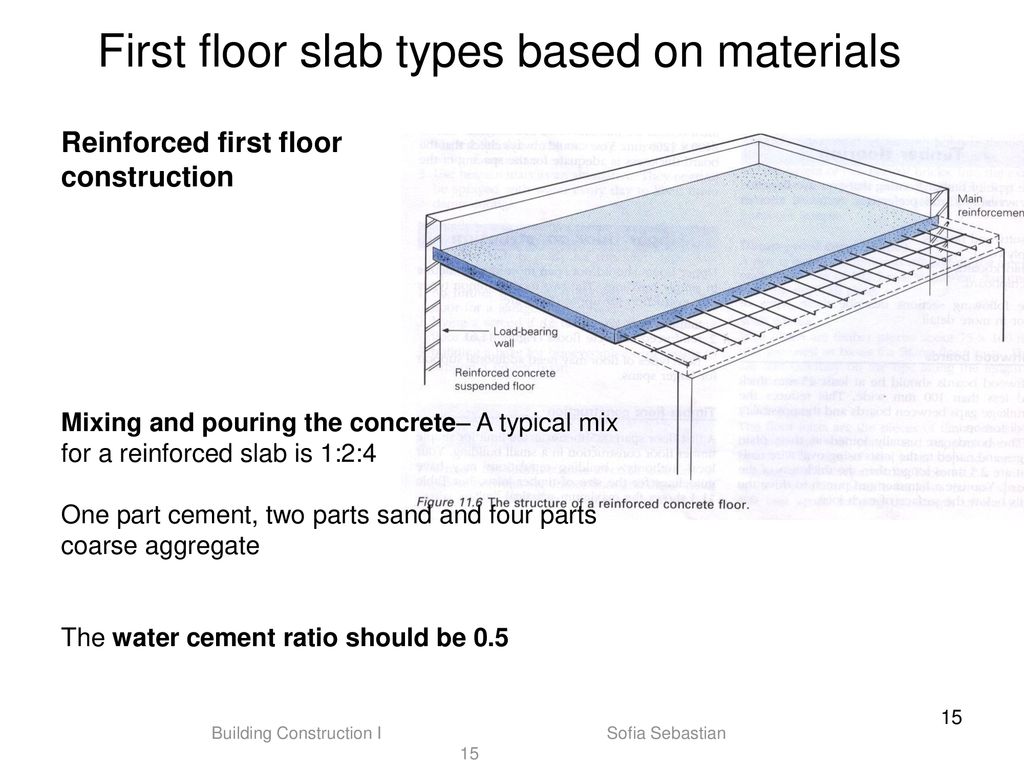

Firstfloor slab thickness The normal thickness used for reinforced concrete slabs in South Africa is 170 mm for small slabs, 255 mm for slabs larger than 5m x 5m and 340 mm thick for longspan slabs forming part of a beam and carrying heavier loads The thickness of a slab will depend on the use and span of the slab Suspended Concrete Floor Slab Specifications Uncategorized Suspended Concrete Floor Slab Specifications viewfloor 2 years ago No Comments Facebook;During the first years of the century suspended timber floors changed A number of improvements were introduced, mostly damp related In the graphic below note that the entire floor is separated from the substructure by the DPCs In addition, the bare earth is covered with a concrete slab (often referred to as an 'oversite') which is at, or above, external ground level to

🕑 Reading time 1 minuteConcrete floor slab construction process includes erection of formwork, placement of reinforcement, pouring, compacting and finishing concrete and lastly removal of formwork and curing of concrete slab ContentsConcrete Floor Slab Construction Process1 Assemble and Erect Formwork for Slab2 Prepare and Place Reinforcement for Slab3 Pour,Suspended slabs are made of concrete and steel mesh, the same as a ground slab They are normally prefabricated offsite, and transported by truck Some slabs have hollow channels running through them these 'hollow core slabs' are used to help reduce weight, and also to allow cabling and piping to be run through the slabStudies of the site, carried out in accordance with Chapter 41 'Land quality managing ground conditions' should be taken into account in the design of substructure Where the depth of infill exceeds 600mm, the floor must be designed as a suspended floor, as described in Chapter 52 'Suspended ground floors' (Design) Loadbearing partitions should not be supported off ground

1

Floors And Flooring Sans Building Regulations South Africa

Suspended concrete slab is referred to a cement slab that is not in contact with the ground This type of and plywood as floor supports for the concrete The forming is very similar to that of framing floor of a house except concrete is a lot heavier than normal residential live load and dead load The 6 inch suspended slab in detail 21 weighs 75 pounds per square foot but theSuspended Timber Ground Floors consist of the finished timber floorboards being attached to floor joists, which are suspended above the subfloor of the foundation These floor joists are raised above the subfloor on small supporting walls called tassel walls (or sleeper walls) A wallplate is then attached to the top of the tassel walls, on which the floor joists rest on A damp proofHomespan Homespan is a revolutionary concrete flooring system consisting of flat precast concrete planks generally 600mm wide and 150mm deep Designed for residential use on both ground and first floor levels, it will carry domestic loading for spans up to 5m and is therefore cost effective Homespan slabs are manufactured to differing lengths

2

5 1 Damp Proofing Concrete Floors Nhbc Standards 21 Nhbc Standards 21

RIW/TD/154 Top of internal concrete retaining wall with ground bearing slab pdf RIW/TD/155 Insulated Concrete Framework & Masonry Below Ground Retaining Wall/Slab Interface pdf RIW/TD/156 Insulated Concrete Formwork & Masonry Below Ground Retaining Wall/Slab Interface Plus Gas Suspended Floor {product_related_downloadscount} Typical housing details pdfUnderfloor heating, suspended timber floor CAD, SKP, JPEG & PDF Files £ 550 CAD File £ 300 Download Type Clear Add to basket Want a discount?First/Second/Third Floor Slab Section Details Fourth Floor Slab Layout plan Fourth Floor Slab Bottom Reinforcement plan Fourth Floor Slab Top Reinforcement plan Fourth Floor Slab Section Details Fifth/Roof Floor Slab Layout plan Fifth/Roof Floor Slab Bottom Reinforcement plan Fifth/Roof Floor Slab Layout plan Fifth/Roof Floor Slab Bottom Reinforcement plan Roof Truss

Insulation For Ground Floors Designing Buildings Wiki

Concrete Vs Timber Floors

Three worked examples of precast unit floors in different building types are also included Structural design guidance provided in previously published three SCI publications, Design of composite beams using precast concrete slabs (P287), Design of asymmetric Slimflor beams with precast concrete slabs (P342)and Design of multistorey bracedConcrete slabs between ground and first floor level greatly reduce sound transfer throughout the dwelling The mass of the slabs mean that they pro vide superior sound resistance to any traditional timber joist system In many cases sound transfer between levels is almost eliminated Fire Resistance A Safer Home The noncombustible nature of con crete makes it one of theInsitu reinforced concrete suspended slabs can be economically designed as flat slabs to Eurocode 2 A flat slab may or may not have dropped sections at beam strips and column supports It may be solid or have a coffered or waffle soffit profile Guidance and the maximum areas of pour and on the location of joints is given in Concrete Advice No 02, Suspended concrete floors

1

Concrete Formwork For Slabs

Thickness of the slab is decided based on span to depth ratio specified in IS Minimum reinforcement is 012% for HYSD bars and 015% for mild steel bars The diameter of bar generally used in slabs are 6 mm, 8 mm, 10 mm, 12mm and 16mm The maximum diameter of bar used in slab should not exceed 1/8 of the total thickness of slabSuspended Concrete floors offer a lot more benefits and are normally made up of either concrete beams (more commonly known as Beam and Block) or concrete planks Both of these systems require a lot of handling and experienced professionals when being fitted Depending on ground conditions, these types of floors will require more support walls in your foundations and a closerSuspended floors are the norm for first floors (and above), but are also excellent for creating a level ground floor over uneven ground Alongside being cheap and easy to construct, timber floors benefit from being able to be adapted on site if need Being timber they are also relatively sustainable (if you ensure you're using sustainably

Articles And Advice Insulation Kingspan Great Britain

P1pcff4 Suspended Concrete Floor Insulation Below Slab Labc

Concrete slabs are a good alternative for small extensions (where beam and block floors are uneconomic) Beam and block systems which utilise insulated blocks can provide an even quicker installation Solutions for first floors include traditional softwood joists, timber Ijoists or open metal web joists;Ground floors Ground bearing solid concrete floors Guidance Diagram 9 Typical section through a ground bearing solid concrete floor and foundation Guidance Table 5 Examples of insulation for ground bearing floor slabs Suspended reinforced in Suspended concrete floors have become popular in UK house construction They are typically used in situations such as sloping sites, areas where the ground has poor bearing capacity, or there is a likelihood of ground volume change If the ground water table is high, or there are aggressive chemicals present in the soil, a suspended floor is often specified

Basic Easy How To Draw A Concrete Slab Section Detail In Autocad Tutorial Youtube

Comparing Ground Floor Structure Costs Homebuilding

Subslab details (ie vapor retarders some times referred to as vapor barriers, insulation, etc,) 11 Concrete moisture conditions and drying rate 12 Special surface finishes, including coatings 13 Adequacy of curing SubGrade and SubBase The subgrade is the ground on which the floor is built The subbase is an optional layer located on top of the subgrade and beneath the slabThis chapter gives guidance on meeting the Technical Requirements for suspended ground floors including those constructed from insitu concrete precast concrete timber joists 521 Compliance 522 Provision of information 523 Contaminants flat slab with drop panel and column head Flat Plate A flat plate is a one or twoway system usually supported directly on columns or loadbearing walls Figure It is one of the most common forms of construction of floors in buildings The principal feature of the flat plate floor is a uniform or nearuniform thickness with a flat soffit which requires only simple formwork and is

How To Design An Ideal Floor For Warehouse And Logistics Facilities

6 Ground Floors Construction Studies

During the first years of the century suspended timber floors changed A number of improvements were introduced, mostly damp related In the graphic below note that the entire floor is separated from the substructure by the DPCs In addition, the bare earth is covered with a concrete slab (often referred to as an 'oversite') which is at, or above, external ground level to316 Timber Frame – Ground floor / separating wall junction – timber suspended floor 317 Timber Frame – Concrete ground floor / separating wall junction – insulation above slab 318 Timber Frame – Concrete ground floor / separating wall junction – insulation below slab 319 Timber Frame – Separating floor / separating wall 3Wide slab flooring is a high quality, economical suspended concrete floor construction using long prestressed concrete floor slabs (or planks) supported by either masonry walls or a supporting frame structure in steel or precast concrete Suitable for all floor levels from ground to roof, this rapid flooring solution is ideal where long spans and/or high load bearing capacities are required

Evolution Of Building Elements

Insulating Below Suspended Timber Floors Ballytherm Co Ukballytherm Co Uk

The original wall damp proof course (DPC) was designed to protect the timbers, skirting boards and plaster from rising damp The damp proof course is usually made from black bitumen, slate or plastic, and should be should be visible below the timber joists By laying a concrete slab you may alter the original level of the floor and bury the DPC Pourinplace Concrete is the first option for concrete slabs and infrastructure, as well as for units such as beams, columns, walls, ceilings, etc Usually, concrete is transported to the site in a nonhardening state and is usually transported in pre concrete trucks Pull a ramp out of the back of the truck and place the concrete in the desired position or into the dumper or pumpThe Speedfloor suspended concrete floor system uses a cold formed steel joist as an integral part of a concrete and steel composite floor The joist is manufactured from pregalvanised high strength steel in a one pass rollformer giving a high degree of accuracy at a fast production rate The ends are simply bolted to the joists which are then ready for transport to site At site, the

Warmfloor Pro Fast Install Insulated Concrete Floor Milbank

Building Guidelines Concrete Floors Slabs

The latter options are more expensive but provide considerable benefits I'm designing a suspended concrete slab over a concrete basement walls for a house garage 24'X24' plan dimension Ideally I would like to avoid beams, but I know locally (Missouri) it has been done with one or two steel W shape beams to support the slab However, this is the first time I am designing/detailing one and want to be sure I cover my bases 09 IRC isCategories Foundations and Floors, Ground Floors s Extension, Timber frame Related Details MG3 – External masonry cavity wall, suspended concrete slab £ 300 –

Fbe 03 Building Construction Science Lecture 3 Floor

Suspended Ground Floor Construction Mezzanine Floor Supplier And Installers Prestressed Concrete

A concrete slab (or suspended beam and block construction) is laid over a damp proof membrane A mm thick piece of insulation is fixed to the perimeter (external) walls, to a height to include the depth of floor insulation and screed Whilst the edging insulation may be on show, it is covered by wall plastering and skirting boards Floor insulation is laid over the whole area and joints areTimber Suspended Floor Detail, Rockwool Insulation £300 vat Add To Basket DWG/DXF/Jpg Block and Beam Floor Details Click Image to Preview Block and Beam Floor Detail, Screed Finish £300 vat Add To Basket DWG/DXF/Jpg Click Image to Preview Block and Beam Floor Detail, Board Finish £300 vat Add To Basket DWG/DXF/Jpg Wall Detail Drawings (Includes Jpeg,Prev Article Next Article Concrete slab floors yourhome fbe 03 building construction science slab on grade foundation design concrete slab floors yourhome Concrete Slab Floors Yourhome Fbe 03

Suspended Floors All You Need To Know Thermohouse

Suspended Floors All You Need To Know Thermohouse

It is also possible to construct suspended concrete floors by using a precast product, for example the popular beam and block system Whichever construction method is used, it is usual to leave concrete surfaces quite rough to provide a key for the cementsand screed Upper floor concrete slabs Workers place concrete on a precast floor slab When it comes to

What Is Slab Construction Types Of Slab Design What Is Floor Slab Types Of Floor Slab Concrete Slabs Thickness Prefabricated Concrete Slabs

Homespan Creagh

Building Construction I Sofia Sebastian 1 Ppt Download

2

Floor Systems Steelconstruction Info

Technical Hub Insulation Boards Kingspan Ireland

Concrete Slab Wikipedia

Greenspec Housing Retrofit Ground Floor Insulation

Ground Floor Insulation Below Concrete Slab Polyfoam Xps

Floor Slab An Overview Sciencedirect Topics

New Home Pouring A First Floor Suspended Slab Youtube

Suspended Ground Floor Slab Reinforcement Avi Youtube

Diagram Of Suspended Timber Floor With Underfloor Heating Pipes Underfloor Heating Floor Heating Systems Hydronic Radiant Floor Heating

Concrete Slab Floors Yourhome

Search Q Suspended Concrete Floor Tbm Isch

Concrete Vs Timber Floors

Concrete Slab Wikipedia

E5mcff30 Suspended In Situ Concrete Floor Insulation Below Slab Labc

Suspended Timber Floor Construction Studies Q1

Fastslab Ground Floor Renovation System

Suspended Floors All You Need To Know Thermohouse

Floors

Build Diy Suspended Concrete Ground Floors

Building Guidelines Drawings Section B Concrete Construction

Evolution Of Building Elements

Detail Post Floor Details First In Architecture

E5smew23 Suspended In Situ Concrete Floor Insulation Below Slab Labc

The New Zealand S First Passive House Concrete Floor Slab Second Pour

Concrete Slab Floors Yourhome

Concrete Slab Floors Yourhome

How To Choose A Floor Structure Homebuilding

The Benefits Of Beam And Block Flooring Build It

A Best Practice Approach To Insulating Suspended Timber Floors Ecological Building Systems

Separate Constructions

Evolution Of Building Elements

Technical Hub Insulation Boards Kingspan Ireland

Floors

Builder S Engineer Suspended Ground Floor Slabs

6 Ground Floors Construction Studies

Cpd 10 18 Flooring Insulation Features Building Design

6 Ground Floors Construction Studies

E5mcpf32 Suspended In Situ Concrete Floor Insulation Below Slab Labc

1

Hollowcore Floors Concrete Products Bison Precast Flooring

6 Ground Floors Construction Studies

Sweet Home 3d Forum View Thread How Can The Floor Be Inside The Top Of The Lower Level

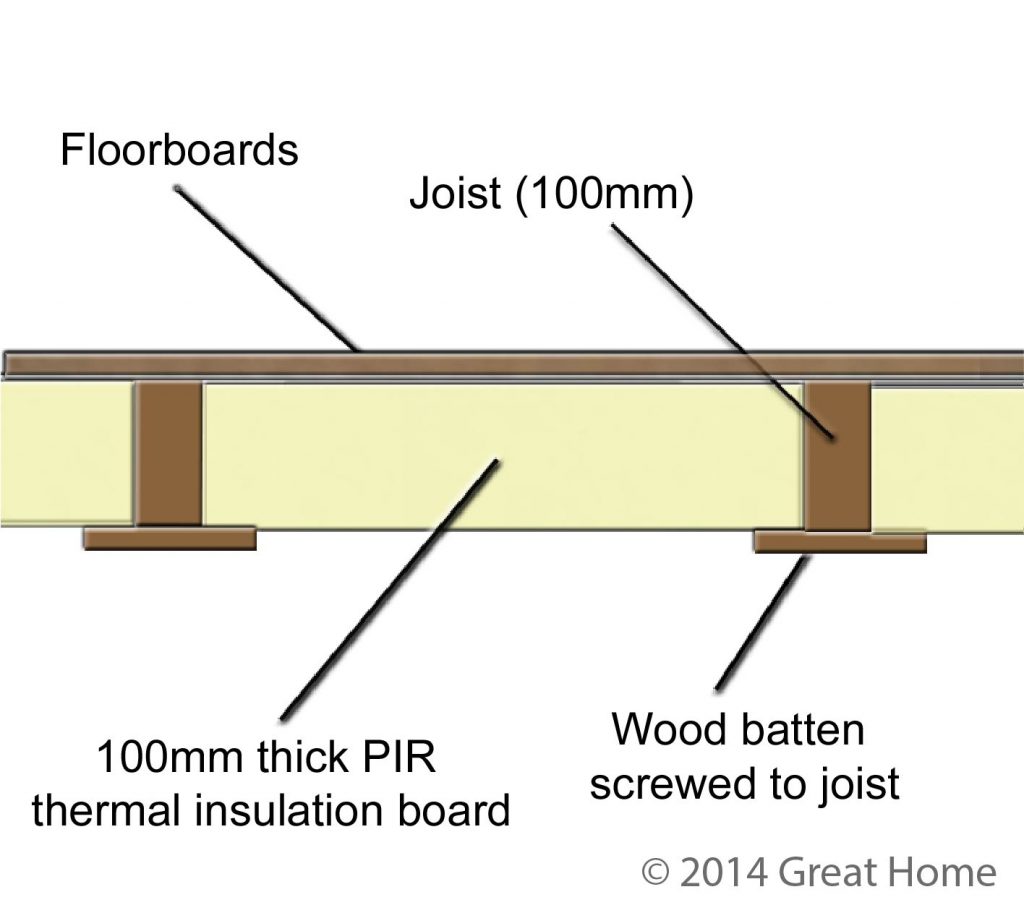

Underfloor Insulation Of Suspended Timber Floors Great Home

6 Ground Floors Construction Studies

Evolution Of Building Elements

Building Construction I Sofia Sebastian 1 Ppt Download

Detail Post Floor Details First In Architecture

Suspended Floors All You Need To Know Thermohouse

Frequently Asked Questions At First Floor Slabs

Solid Ground Floor Wikipedia

Traditional Solid Ground Floors

6 4 7 Precast Concrete Nhbc Standards 21 Nhbc Standards 21

Suspended Floors All You Need To Know Thermohouse

Concrete Slab Floor Construction Branz Renovate

Floor Framing Structure

Defects By Decade Local Surveyors Direct

Building Guidelines Concrete Floors Slabs

Concrete Vs Timber Floors

Building Guidelines Concrete Floors Slabs

Prestressed Concrete First Floor First Floors Slab Construction Suspended Precast Concrete Floor

Detail Post Floor Details First In Architecture

Floor Concrete Soffits

Suspended Floors All You Need To Know Thermohouse

Concrete Slab Abis

Floor Detail Drawings

Ground Level Concrete Slab Subfloor Build

Farm Structures Ch5 Elements Of Construction Floors Roofs

Insulating Above A Groundbearing Slab Design Guidance Ballythermballytherm Co Uk

First Floor Concrete Slabs What You Need To Know Eco Built

Floor Detail Drawings

Figure B 10 Figure B 10 Alternative Floor Slab Detail The Suspended Reinforced Concrete Garage Workshop Plans Concrete Structural Drawing

2

Concrete Floor Slab Construction Process The Constructor

Detail Post Floor Details First In Architecture

Greenspec Housing Retrofit Ground Floor Insulation

Structure Magazine Creating An Opening In Existing Floors

Eurima Suspended Concrete Floors

5 Things To Look For When Inspecting A Suspended Concrete Slab

0 件のコメント:

コメントを投稿